- Home

- Industries

- Electric Vehicle

Electric Vehicle

Innovative, High-Efficiency, and Sustainable EV Manufacturing

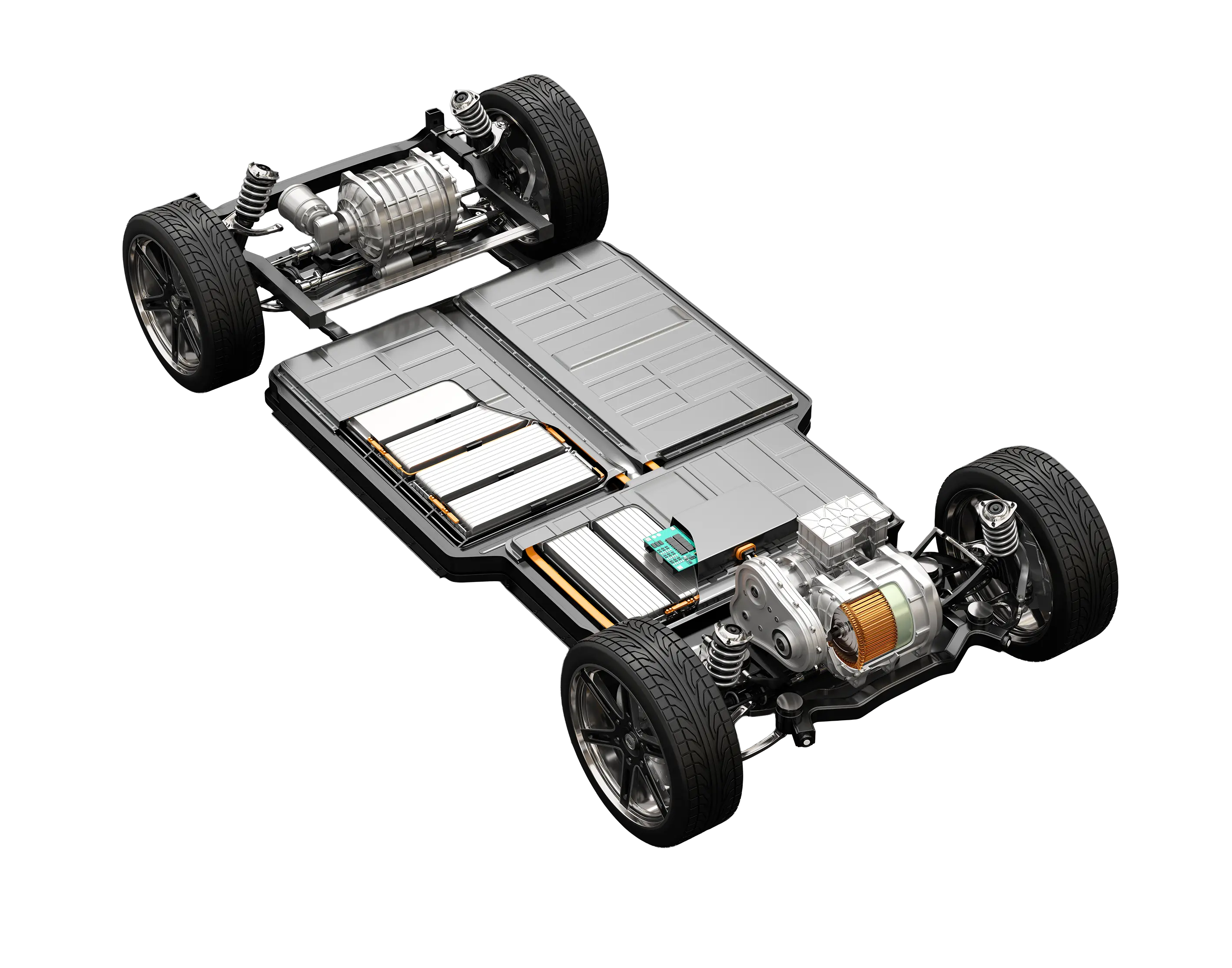

CEIA USA delivers cutting-edge induction heating systems tailor-made for the electric vehicle (EV) sector which addresses the unique demands of battery modules, power electronics, e-motors, and advanced assemblies. From brazing and bonding to shrink fitting, heat treatment, and precise thermal management, our solutions ensure EV components are built for performance, longevity, and sustainability.

Request a Consultation to discover how CEIA USA can elevate your EV production line with cleaner, faster, and more reliable manufacturing.

Driving EV Manufacturing Forward with Induction Heating

Battery Tab & Busbar Soldering / Brazing

For joinery in battery packs there are busbars, copper/aluminum tabs which CEIA USA’s induction heating delivers high conductivity, repeatable joints, and minimal thermal risk to nearby cells or insulation. Critical for safe, efficient battery modules and pack durability.

Adhesive & Bonding / Module Enclosure Assembly

EV components require strong, precise bonding of module enclosures, potting, adhesives, or insulation systems. Induction heating enables rapid adhesive curing and bonding with precision, enabling faster cycle times without compromise to sensitive materials.

Motor, Stator & Rotor Assembly & Shrink Fitting

Shrinking motor casings or joining rotors/stators demands tight tolerances and stress-free assembly. CEIA USA induction solutions provide controlled shrink fitting and fit-up, ensuring mechanical integrity and optimal performance for EV e-motors.

Heat Treatment of EV-Specific Components

EV gears, shafts, and power electronics housings demand wear resistance, hardness, and precise microstructure. CEIA USA systems support surface hardening, stress relieving, and annealing to meet these material performance standards.

Key Electric Vehicle Applications

Application |

Common Components |

Benefits |

|

Busbar / Tab Soldering & Brazing

|

Copper / aluminum tabs, battery busbars

|

High conductivity, minimal heat-damage, reliable joints

|

|

Adhesive & Module Bonding

|

Battery enclosure panels, insulation sheets

|

Uniform cure, strong bonding, faster assembly

|

|

Surface Hardening & Heat Treatment

|

EV gears, shafts, housing components

|

Improved wear resistance, fatigue strength

|

|

Thermal Management & Enclosure Assemblies

|

Power electronics housings, cooling jackets

|

Efficient heat flow, reduced thermal stress

|

Partner With CEIA USA for Electric Vehicle Innovation

From battery pack brazing and module bonding to motor assembly, surface hardening, and thermal management, CEIA USA provides precision, reliability, and sustainable performance for the EV industry.

CEIA USA Expertise in EV & Induction Technology

CEIA USA brings decades of experience to the EV sector. Our induction heating systems are designed for precision, repeatability, and energy efficiency, collaborating with OEMs and Tier-1 suppliers to meet stringent performance requirements. Our Capabilities Include:

- Automated induction brazing / soldering lines for battery and power electronics

- Advanced coil design and integration for stator & rotor assemblies

- Real-time temperature monitoring and closed-loop control systems

- Programmable thermal profiles, for precise multi-step control over the entire heating process.

Experience and Authority

CEIA USA has worked with leaders in EV production to refine processes that deliver repeatable performance, certified quality, and reliable durability. Our engineers have deep expertise in handling heat-sensitive materials and complex component assemblies, contributing to safer, higher-performing EV systems.

Sustainable and Energy-Efficient EV Manufacturing

Induction heating supports sustainable manufacturing in the EV industry by offering:

- Localized heat with minimal energy waste

- Reduced carbon footprint through clean, contact-less heating

- Faster cycle times, less rework, lower waste

- Enhanced safety and lower operational emissions

By incorporating CEIA USA’s induction heating technology, manufacturers can drive forward green mobility, EV efficiency, and production sustainability.