- Home

- Industries

- Automotive

Automotive

Efficient, Reliable, and Sustainable Automotive Production

CEIA USA delivers high-performance induction heating systems designed for precision, speed, and repeatability in the automotive industry. From surface hardening and brazing to shrink fitting, bonding, and heat treatment, our solutions ensure superior quality and efficiency in every component.

Request a Consultation to explore how CEIA USA can enhance your manufacturing line’s performance and sustainability.

Driving the Future of Automotive Manufacturing with Induction Heating

Surface Hardening for Durability

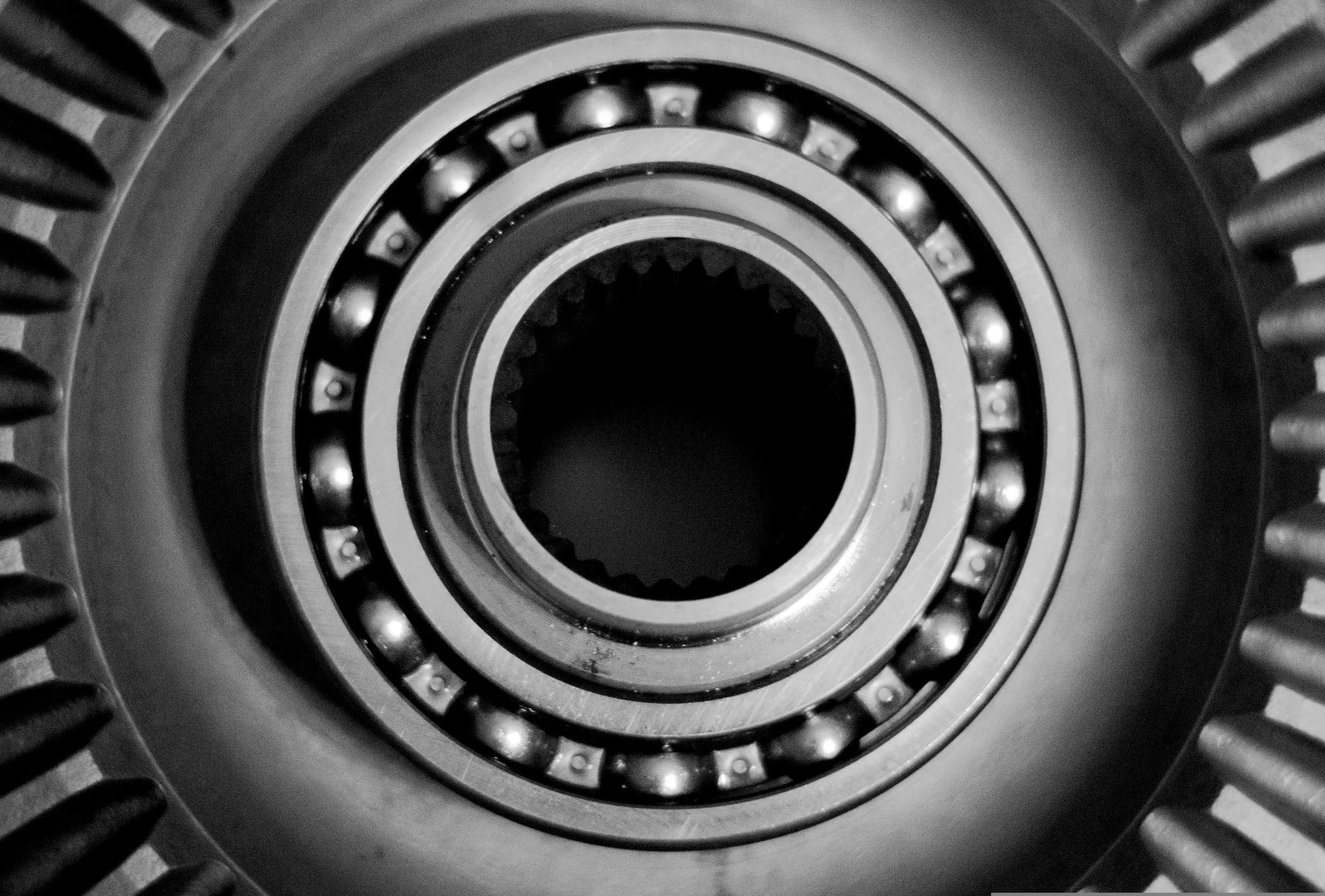

Automotive components such as shafts, gears, and camshafts demand strength and wear resistance. CEIA USA induction systems provide precise surface hardening, improving fatigue life while maintaining dimensional integrity which is ideal for transmissions, drive systems, and engine components.

Brazing and Joining Solutions

For copper, aluminum, and steel components, CEIA USA offers automated induction brazing systems that deliver consistent, oxidation-free joints. These solutions are used for air conditioning lines, fuel systems, sensors, and electrical connectors, meeting strict automotive production standards.

Shrink Fitting and Assembly Applications

Induction heating enables fast, distortion-free shrink fitting for components such as bearings, rotors, stators, and gear rings, ensuring tight tolerances and repeatable accuracy across high-volume assembly lines.

Heat Treatment for Structural Integrity

Our technology allows controlled heating for stress relieving, annealing, and tempering, crucial for maintaining the structural performance of suspension arms, axles, and steering systems.

Key Automotive Applications

Application |

Common Components |

Benefits |

| Surface Hardening | Gears, shafts, camshafts | Increased durability and fatigue resistance |

| Brazing | A/C lines, sensors, connectors | Leak-proof joints, repeatable precision |

| Shrink Fitting | Bearings, rotors, stators | Tight, uniform fits without damage |

| Annealing | Axles, structural parts | Reduced stress, improved machinability |

| Bonding | Battery modules, sensors | Fast curing, high structural integrity |

Partner With CEIA USA for Automotive Innovation

From surface hardening gears and shafts to brazing EV connectors and bonding battery modules, CEIA USA delivers reliable, sustainable, and precise induction heating technology for the evolving automotive landscape.

CEIA USA Expertise in Automotive Induction Heating

CEIA USA’s decades of experience make us a trusted partner to leading OEMs and Tier-1 suppliers worldwide. Our induction systems deliver consistent heating, precise temperature control, and minimal energy waste, enabling manufacturers to achieve higher productivity and quality.

Our Capabilities Include:

- Automated systems for high-volume production

- Real-time temperature monitoring and closed-loop control

- Tailored coil designs for complex geometries

- Integration with Industry 4.0 smart manufacturing systems

Experience and Authority

CEIA USA engineers collaborate closely with automotive manufacturers on electric vehicle (EV) and hybrid powertrain applications, including battery assembly, stator curing, and busbar brazing. Our experience spans steel, aluminum, and copper applications in ICE and EV platforms alike.

Sustainable and Energy-Efficient Manufacturing

Induction heating aligns perfectly with sustainable automotive manufacturing by minimizing waste and maximizing efficiency. CEIA USA technology supports energy-efficient heating processes that reduce carbon emissions while maintaining production quality.

Benefits include:

- Up to 50% less energy consumption compared to traditional heating methods

- Cleaner operations with no open flame or emissions

- Improved worker safety and reduced operational costs

By integrating sustainable induction solutions, CEIA USA helps the automotive sector accelerate toward greener mobility and efficient EV production.