The Power Cube Series 900 Generators provide high power output and minimal operating costs, featuring compact design and small heating heads. They ensure stable performance with built-in self-diagnosis and comply with electrical safety and electromagnetic regulations.

Hard Brazing

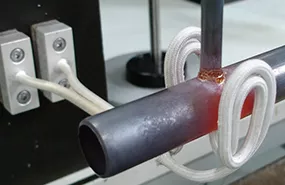

Hard brazing, also known as high-temperature brazing, is a metal-joining process that uses a filler metal with a melting point above 450°C (typically between 600°C and 1200°C) to bond two or more metal components. Unlike welding, the base materials are not melted. Instead, capillary action draws the filler metal into the joint, creating a strong, sealed connection.

This method is ideal for joining dissimilar metals, such as steel to copper or stainless steel to aluminum, and is commonly used in industries like automotive, aerospace, HVAC, and electrical manufacturing. Hard-brazed joints are known for their strength, corrosion resistance, and ability to withstand high temperatures and pressure

Precise temperature control and uniform heating are critical in hard brazing to ensure proper filler flow and joint integrity without overheating or damaging the base materials. Induction heating is especially well-suited for this process, as it offers fast, localized, and repeatable heating with minimal thermal stress to surrounding components.

CEIA generators support this demanding process by providing stable and accurate induction heating, allowing operators to achieve consistent brazing quality across various materials and geometries.