The Power Cube Series 900 Generators provide high power output and minimal operating costs, featuring compact design and small heating heads. They ensure stable performance with built-in self-diagnosis and comply with electrical safety and electromagnetic regulations.

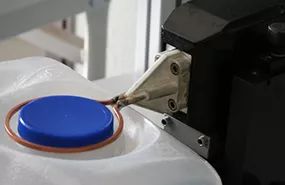

Cap Sealing

Induction cap sealing is a process in the packaging industry, used to bond a foil liner to the rim of a container. This is typically done with plastic or glass bottles. This hermetic seal serves multiple purposes: it provides tamper evidence, prevents leaks, and helps preserve product freshness and shelf life.

The process relies on a high-frequency electromagnetic field to heat the foil liner inside the cap. As the bottle passes under the induction coil, the foil rapidly heats, melting the polymer layer and sealing it to the container. The heating is fast, non-contact, and highly localized, which minimizes heat exposure to the cap and product.

Precision and repeatability are essential because the sealing must happen within milliseconds on high-speed lines. Undercooked seals can result in leaks, while overheating may deform packaging. That's why reliable power control, thermal stability, and integration with automation systems arekey.

CEIA's high-frequency induction systems are often used in cap sealing applications for their efficiency, fine power adjustment, and control interfaces. This enables consistent performance even under demanding production conditions. Due to its speed, cleanliness, and reliability, induction cap sealing remains a preferred method across industries like food and beverage, pharmaceuticals, and cosmetics.