The Power Cube Series 900 Generators provide high power output and minimal operating costs, featuring compact design and small heating heads. They ensure stable performance with built-in self-diagnosis and comply with electrical safety and electromagnetic regulations.

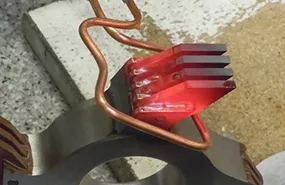

Tool Brazing

Tool brazing is a specialized process that joins cutting inserts, carbide tips, or hardened steels to tool bodies such as drills, saw blades, or milling cutters. The goal is to form a strong, durable joint capable of withstanding high mechanical and thermal stress during operation.

Unlike welding, brazing does not melt the base materials. Instead, it uses a filler metal that flows between the joint surfaces by capillary action, typically with a melting point between 600°C and 1200°C. This ensures high joint integrity for tools while preserving the metallurgical properties of both the cutting material and the tool body.

Precision is essential. The heat must be applied rapidly and locally to avoid affecting the temper of the tool or creating internal stresses.

Induction heating is ideal for tool brazing because it provides fast, targeted heating with high repeatability and minimal distortion. It also enables consistent quality across production batches, which is especially important in industries where tool performance and longevity directly impact efficiency and cost.

CEIA’s induction systems are often chosen for tool brazing applications due to their compact design, precise power control, and energy efficiency. Combined with advanced control units, they support consistent heating cycles, optimize filler flow, and reduce the risk of overheating or weak joints.