The Power Cube Series 900 Generators provide high power output and minimal operating costs, featuring compact design and small heating heads. They ensure stable performance with built-in self-diagnosis and comply with electrical safety and electromagnetic regulations.

- Home

- Applications

- Tin Soldering

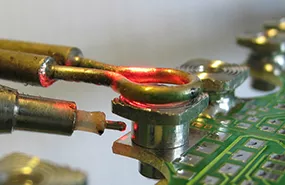

Tin Soldering

Soldering in industrial environments demands high control, precision, and repeatability, especially when working with delicate components or complex assemblies. Success depends on accurately managing heat delivery, solder volume, and timing throughout the process.

CEIA Induction soldering systems include advanced features like closed-loop control, automated solder feed, and programmable process parameters to ensure consistency across high-volume production runs.

This level of control is fundamental in industries such as electronics, automotive, and electrical manufacturing, where joint integrity and quality assurance are critical.

One example of such an advanced solution is CEIA’s 900 Series soldering platform, which includes compact, patented solid-state generators and dedicated control units, often paired with CEIA's wire fed solder applicators. These systems offer high energy efficiency (over 95%) and deliver precise, repeatable heat for consistently strong solder joints.

Preferred products

Free Application Analysis

Complimentary sample testing

Fast Quotes