Induction Coil

CEIA's custom-designed induction heating coils are engineered to work seamlessly with CEIA heating heads and power supplies, forming a fully integrated system tailored to each application’s thermal and geometric requirements.

Each coil is developed in close coordination with the heating head’s electrical characteristics, ensuring optimal impedance matching, efficient power transfer, and precise energy delivery. From complex geometries to demanding duty cycles, these coils are built to meet exacting specifications with reliability and repeatability.

Key Points

Open Coils

Coils that do not fully enclose the part, providing flexibility and easy access for complex assemblies or continuous processes.

Pancake Coils: Flat, spiral-wound coils for heating planar surfaces, edges, or flanges. Ideal for brazing, bonding, and surface treatment with limited vertical clearance.

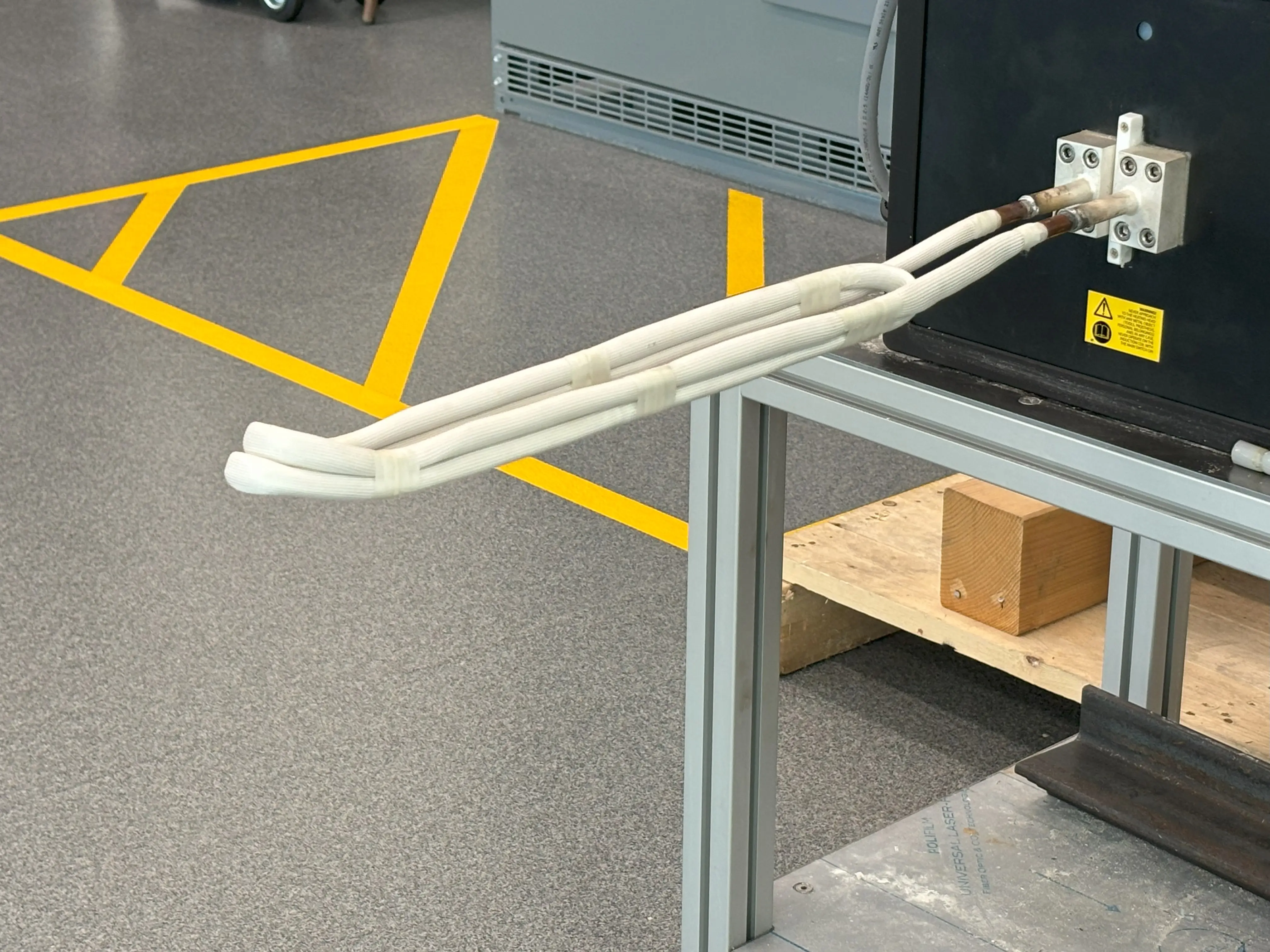

Hairpin Coils: U-shaped coils with parallel legs, creating a focused linear heating zone. Common for scanning, strip heating, or localized processing of straight sections.

Butterfly Coils: Symmetrical open coils that distribute heat evenly across wide or irregular surfaces. Suited for large flat parts or assemblies with variable profiles.

U-Shaped Coils: Open-form coils that apply heat to targeted sections of a component, such as joints, corners, or discrete features.

Channel Coils: Open rectangular or oval coils for continuous heating of billets, bars, tubes, or strip stock moving through the heating zone.

Split (Clamshell) Coils: Hinged or segmented coils that open and close around the workpiece, offering strong coupling with the flexibility to process closed-loop or in-line parts.

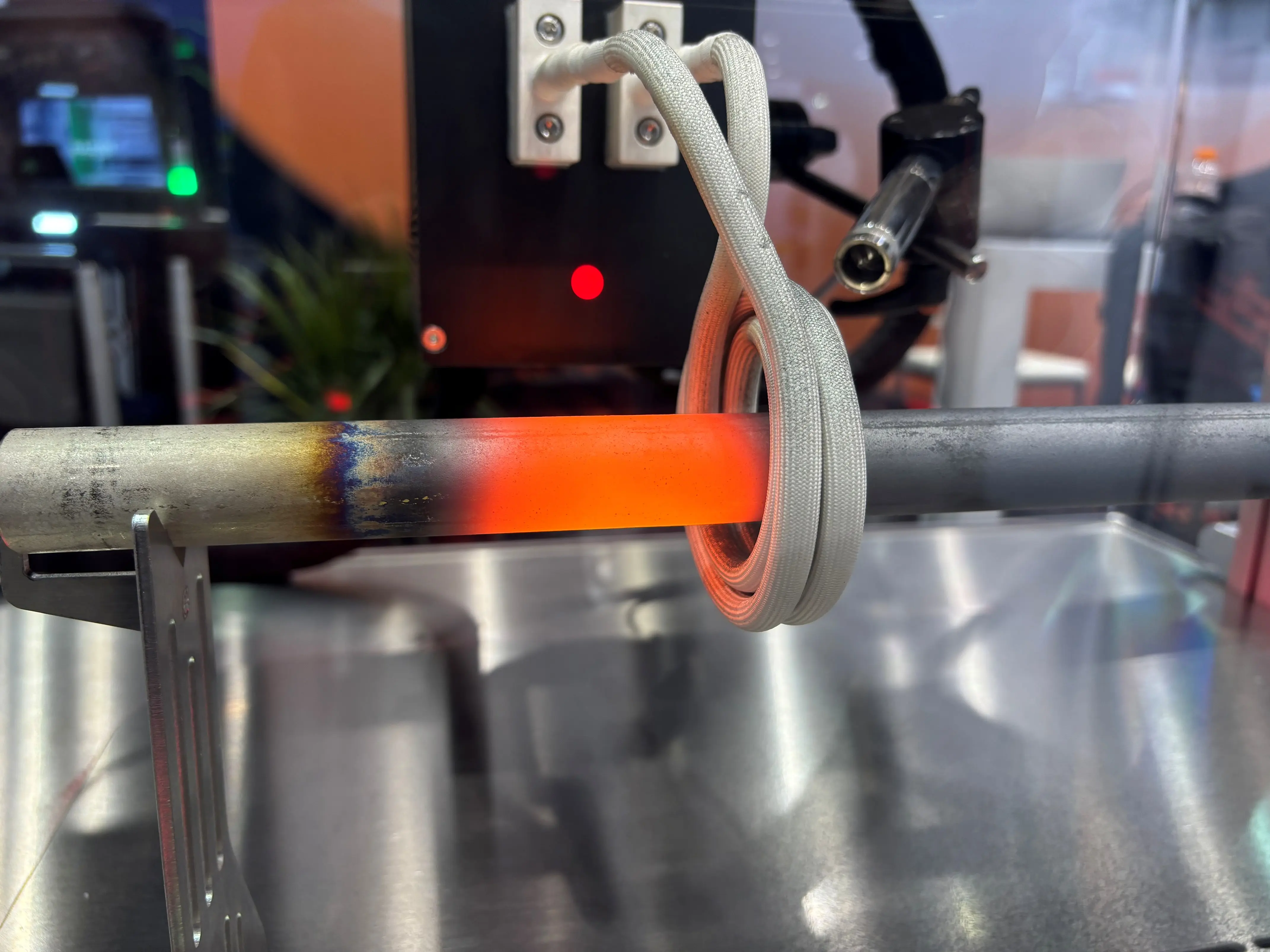

Transverse-Flux (Headphone-Style) Coils: Paired opposing coils that generate a lateral magnetic field, effective for brazing tubing, pipes, or components with complex or asymmetrical geometries.

Closed Coils

Coils that fully encircle the workpiece, providing strong magnetic coupling and uniform field distribution for high-performance heating of rotationally symmetric or enclosed parts.

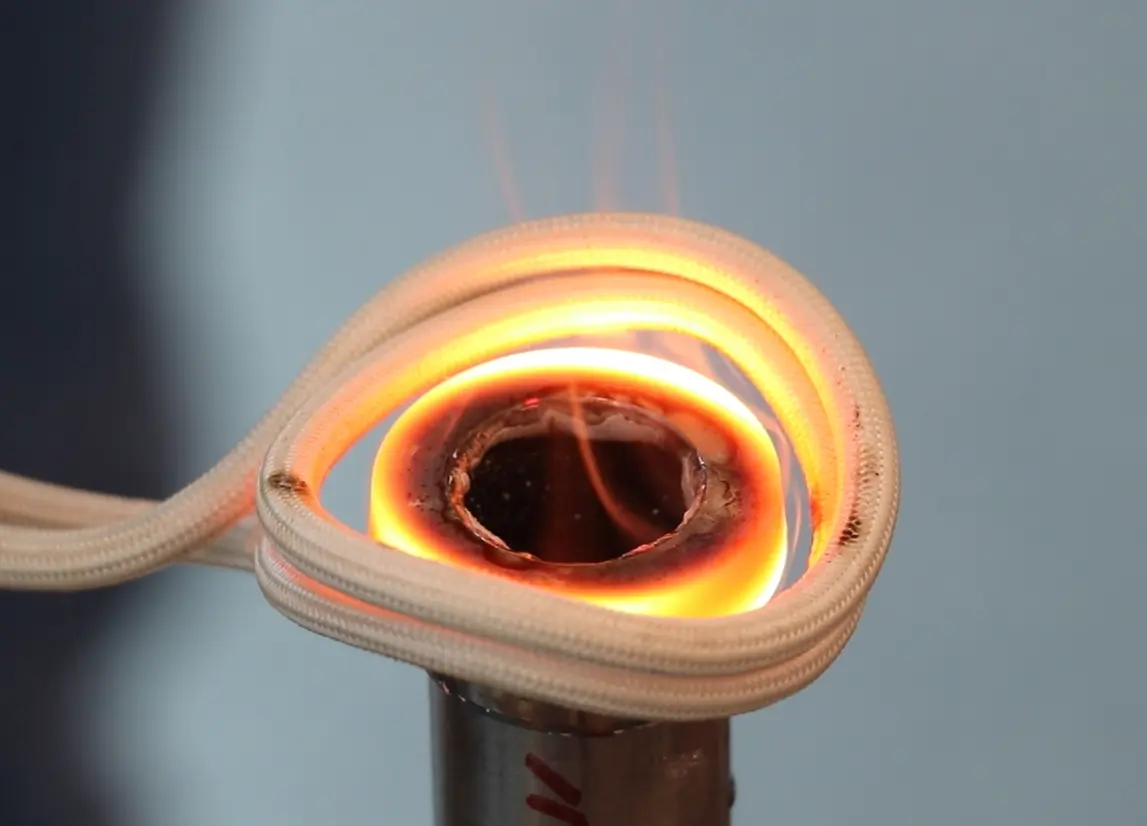

Single-Turn Coils: Compact, single-loop coils used for high-intensity, localized surface heating. Well suited for short cycle times and concentrated energy delivery.

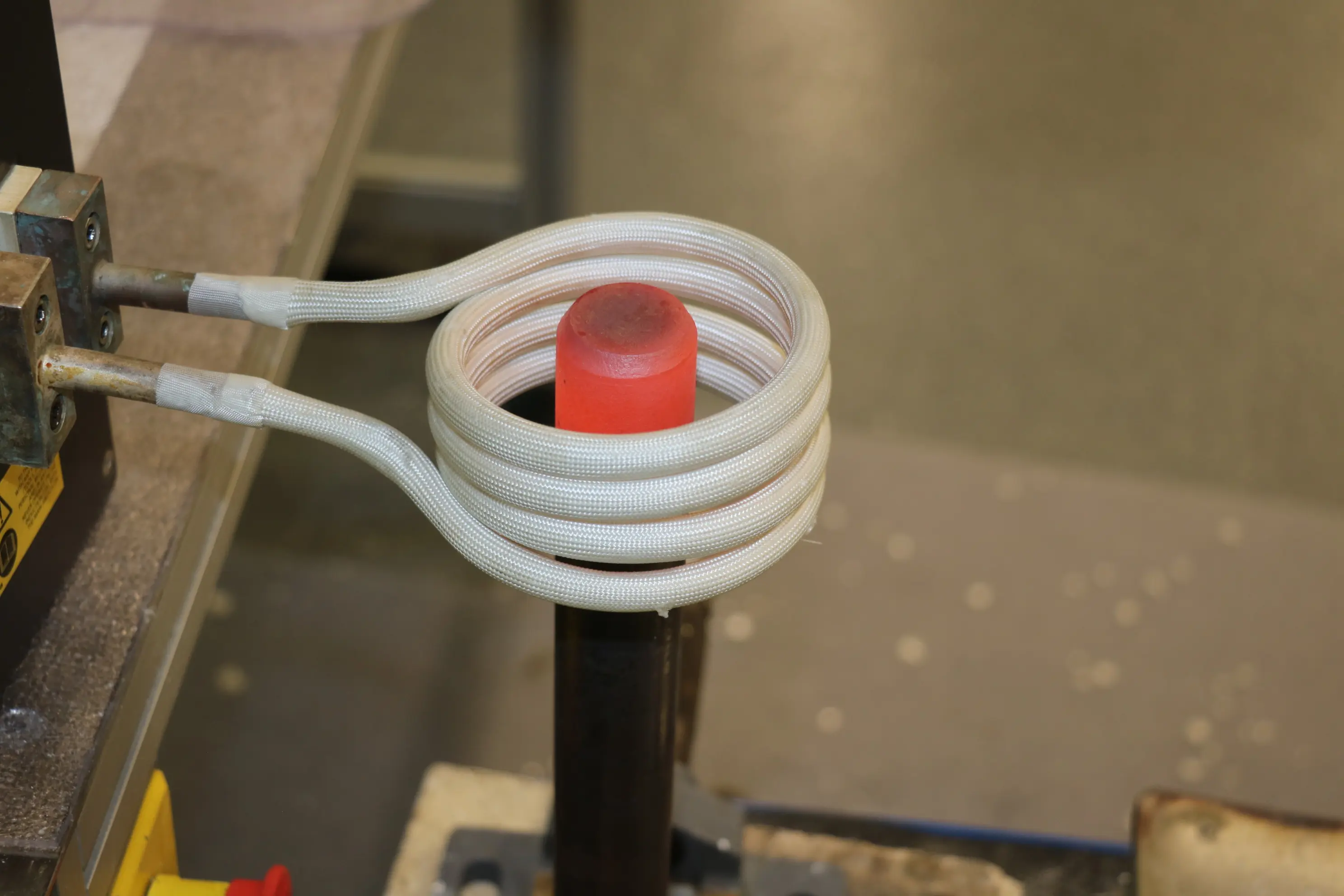

Multi-Turn Coils: Multiple-turn coils, wound concentrically or helically, to achieve greater penetration depth and uniform heating across thicker cross-sections.

Helical Coils: Cylindrical spiral coils wrapped around round parts such as shafts, rods, or tubes, providing consistent radial heating for through-heating or surface hardening.

Concentrator Coils: Closed-loop coils incorporating magnetic flux concentrators to intensify field strength and improve heating efficiency on low-conductivity or high-mass parts.

Internal Heating Coils: Coils designed to fit within bores, cavities, or internal diameters, delivering controlled heating from the inside out. Used in shrink fitting, bore brazing, and internal processing of hollow components.

Contour Coils: Custom-shaped coils formed to follow the external profile of complex parts, ensuring even heating across non-uniform or intricate surfaces.

Refractory-Lined Forge Coils: Robust, closed-loop coils lined with refractory materials to withstand the high temperatures of billet and bar forging. Engineered for reliable long-duration heating and efficient thermal transfer in demanding forging applications.