The SA/80 Generator Series is a high power induction unit in a very compact size with embedded advanced microprocessor based control software and state-of-the-art electronics. This allows very high efficiencies (>96%) under a wide variety of workload conditions while maintaining precise, stable and repeatable output power.

- Home

- Applications

- Induction curing

Induction curing

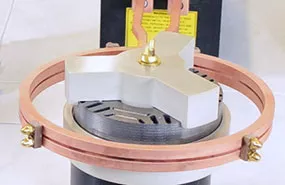

Induction curing is a process that uses localized electromagnetic heating to initiate chemical and molecular changes in polymer-based materials such as epoxies, phenolics, polyesters, and silicones. These materials are commonly applied for bonding, sealing, coating, insulating, and protecting components across a wide range of industrial products.

CEIA induction heating systems are widely used for curing applications, particularly in the automotive industry and the production of electrical power cables. The ability to apply heat precisely where needed, along with fast cycle times and accurate temperature control, makes induction curing ideal for high-throughput, quality-critical environments. The process offers several advantages, including repeatability, stable power output, localized heating, and reliable thermal regulation. These features contribute to faster production, energy savings, and improved quality control of the finished product.

Unlike conventional curing methods that heat entire assemblies or require prolonged oven exposure, induction curing delivers targeted, on-demand heat that minimizes thermal stress on surrounding materials and components. This not only enhances energy efficiency but also supports automation and inline production. Whether curing adhesives in structural joints or insulating layers in electrical cables, induction curing provides manufacturers with a clean, efficient, and scalable solution for consistent, high-performance results.

Preferred products

Free Application Analysis

Complimentary sample testing

Fast Quotes