The Power Cube Series 900 Generators provide high power output and minimal operating costs, featuring compact design and small heating heads. They ensure stable performance with built-in self-diagnosis and comply with electrical safety and electromagnetic regulations.

- Home

- Applications

- Heating Treatment

Heating Treatment

Heat treating is a thermal process used to alter metals' physical and mechanical properties, typically to increase hardness, improve wear resistance, relieve internal stresses, or enhance ductility. It's widely applied in manufacturing industries such as automotive, aerospace, toolmaking, and heavy equipment.

Standard heat treatment processes include hardening, tempering, annealing, normalizing, and stress relieving. These methods involve carefully controlled heating and cooling cycles, often requiring specific temperatures, durations, and cooling rates based on the material and desired outcome.

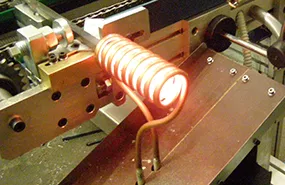

Induction heating has become a preferred method for heat treating due to its speed, precision, and efficiency. It allows localized heating, making it ideal for surface hardening or treating specific zones of a part, such as gears, shafts, and bearing surfaces, without affecting the core structure. The process is also clean, repeatable, and easy to automate, supporting modern production environments.

Induction heat treating delivers improved part performance, reduced distortion, and high production throughput, making it a vital process in precision manufacturing and high-demand industries.

CEIA induction systems deliver fast, efficient heating with precise control, which is ideal for executing complex heat treatment cycles.