What Is Shrink Fitting and How Does Induction Heating Help?

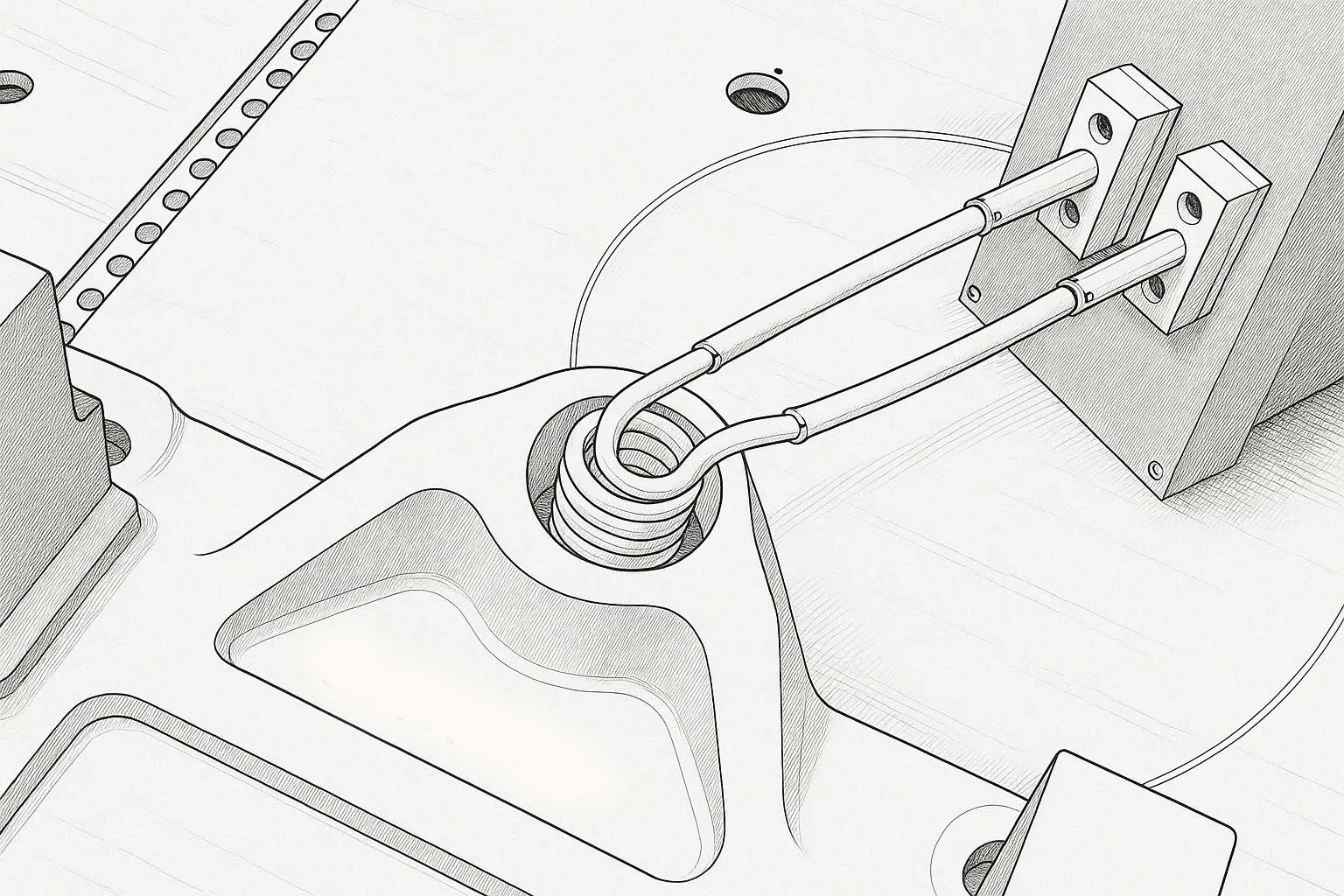

Shrink fitting joins two parts by heating the outer piece so it expands and fits over the inner one. As it cools, it contracts and grips tightly, creating a strong, precise fit without adhesives or fasteners. Compared to slower methods like ovens, induction heating is faster, cleaner, and ideal for modern production.

Shrink fitting is a mechanical joining process used across manufacturing industries to achieve strong, permanent assemblies without the need for adhesives, welds, or fasteners. It works by using thermal expansion and contraction. The outer component is heated until it expands, allowing it to slide over an inner component. As the outer part cools, it contracts and grips the inner part tightly, forming a secure, interference fit.

This method is beneficial in applications that require:

- Precision

- Durability

- Elimination of secondary fastening steps

Despite the name, shrink fitting doesn’t involve shrinking anything during the process. The “shrink” happens as the heated component cools and returns to its original size, locking it in place around the mating part. This is very different from what most people associate with “shrink wrap” in packaging.

Common Use Cases:

- Gears mounted on shafts

- Bearings or sleeves fitted onto assemblies

- Retaining rings or housings pressed into position

Traditional Shrink Fitting Methods

While induction heating is widely used today, manufacturers have relied on other heating methods for years. Here are some common ones and the issues they present:

1. Oven Heating

How it works: Parts are placed in an industrial oven and heated slowly until thermal expansion allows for assembly.

Challenges with this approach:

- Very long heat-up times, often several hours

- Heats the entire oven rather than the part directly

- All parts must remain at the fitting temperature until the final component is assembled

- Inefficient for single parts or small batches

- Unwieldy due to space constraints and burn risk during handling

2. Open Flame (Torch Heating)

How it works: A torch, typically an oxy-acetylene torch, is used to heat the part manually.

Challenges with this approach:

- High chance of localized overheating or surface damage

- Safety risks due to the use of open flames

- Low consistency from one part to the next

- Not ideal for automated or high-volume production

3. Hot Oil Baths

How it works: Parts are submerged in heated oil to reach the necessary expansion temperature.

Challenges with this approach:

- Creates a messy, high-maintenance work area

- Safety and environmental concerns from fumes and potential fire

- Oil can contaminate assemblies

- Heat-up and cool-down take longer compared to other methods

4. Hot Air Guns or Furnaces

How it works: Hot air is directed at the part using blowers or heated chambers.

Challenges with this approach:

- Slow and energy-intensive

- Poor temperature precision

- Heat spreads over large areas instead of targeting specific zones

- May not achieve uniform heating on complex parts

Why Induction Heating Is the Preferred Option

Induction heating offers a faster, cleaner, and more automatable alternative to these older approaches. It applies focused heat directly into the part, making it incredibly efficient for precision fits and repeatable processes.

Key benefits:

- Rapid, direct heating of the part

- Lower energy use and operating costs

- No flames, fumes, or contact with oils

- Improved safety and cleaner work conditions

- Easy to integrate into automated production lines

For manufacturers seeking to enhance speed, reliability, and quality in shrink fitting, induction heating is the more effective long-term solution.