Key Safety and Environmental Benefits

When it comes to joining metal components, brazing is a widely used technique across various industries. However, traditional brazing methods often come with significant risks and environmental drawbacks. In this blog, we'll explore the safety concerns associated with conventional brazing techniques and how induction brazing offers a safer, more efficient alternative.

Common Risks with Traditional Brazing Methods

Traditional brazing methods, such as torch brazing, involve the use of open flames and flammable gases.

These methods pose several risks, including:

- Fire hazards: Open flames can ignite nearby flammable materials, causing fires or explosions.

- Operator injuries: Direct exposure to flames can result in burns or other injuries.

- Poor temperature control: Manual control of flames can lead to inconsistent heating, potentially damaging components or creating weak joints.

- Environmental impact: The use of flammable gases contributes to air pollution and increases the carbon footprint of the brazing process.

How Induction Brazing Eliminates Open Flames and Gas Hazards

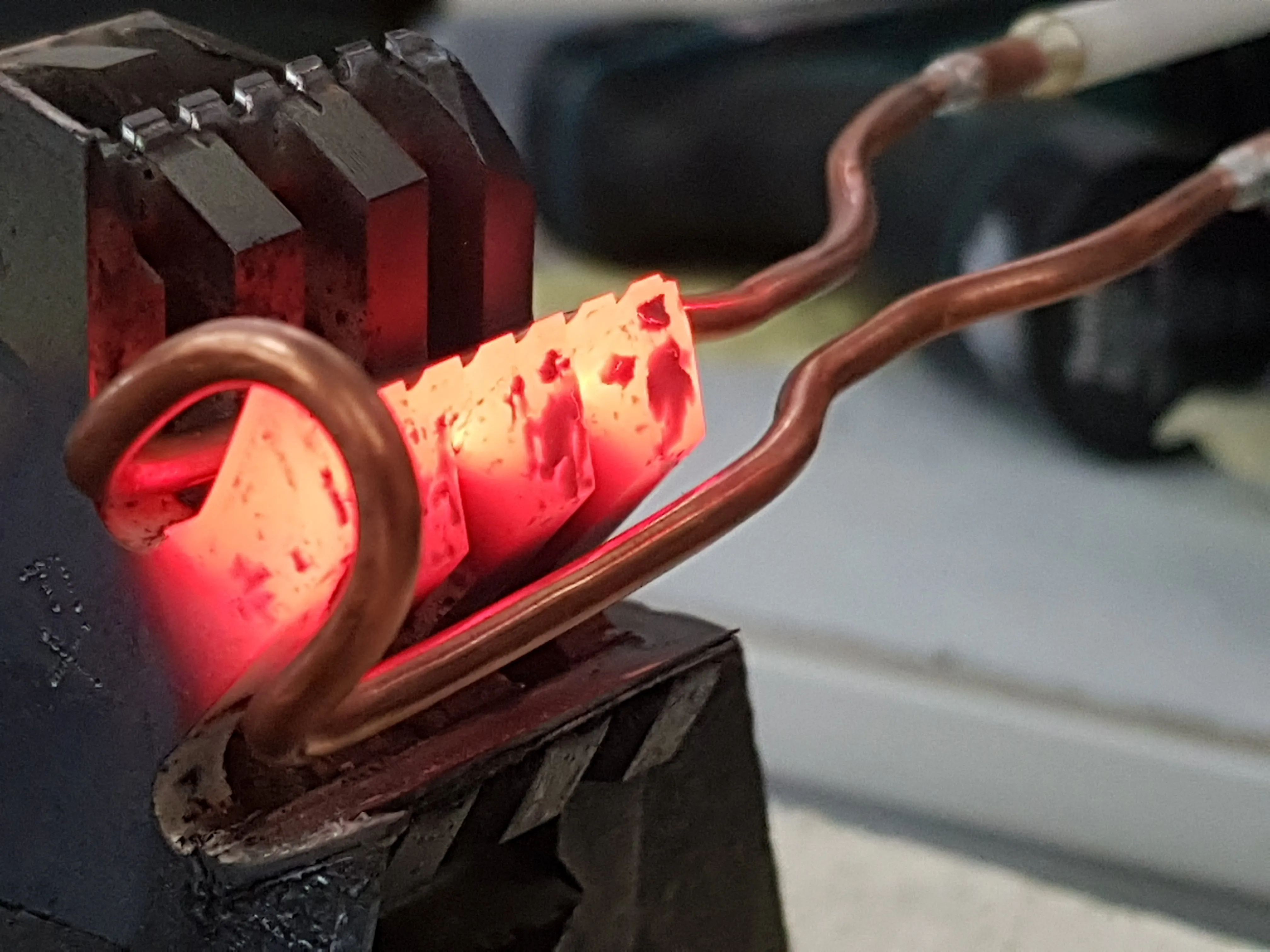

Induction brazing eliminates many of the risks associated with traditional brazing methods by using electromagnetic induction to heat components. This process involves generating a high-frequency electromagnetic field that induces heat directly within the metal workpiece, without the need for open flames or gases.

The benefits of induction heating brazing include:

- No open flames: Induction brazing is a flameless process, reducing the risk of fires and operator injuries.

- No gas hazards: The absence of flammable gases minimizes the risk of explosions and reduces air pollution.

- Precise temperature control: Induction brazing machines offer precise control over the heating process, ensuring consistent results and minimizing the risk of component damage.

Operator Safety and Temperature Control Advantages

One of the key advantages of induction brazing is its ability to enhance operator safety. By eliminating open flames and providing precise temperature control, induction brazing machines create a safer working environment.

- Reduced risk of burns: Without open flames, operators are less likely to suffer burns or other injuries.

- Improved process control: Precise temperature control ensures that components are heated to the correct temperature, reducing the risk of damage or defects.

- Consistent results: Induction brazing produces consistent, high-quality joints, minimizing the need for rework or repairs.

Cleaner, More Energy-Efficient Work Environments

Induction brazing not only improves safety but also contributes to a cleaner, more energy-efficient work environment.

- Reduced energy consumption: Induction heating brazing is highly efficient, converting most of the input energy into useful heat.

- Minimized environmental impact: The absence of open flames and flammable gases reduces air pollution and minimizes the carbon footprint of the brazing process.

- Cleaner workspace: Without the soot and fumes associated with traditional brazing methods, the workspace remains cleaner and healthier for operators.

CEIA USA's Built-in Safety Features and Compliance Standards

CEIA USA is a leading manufacturer of induction brazing machines that prioritize safety and efficiency. Their machines are designed with built-in safety features and comply with international safety standards.

- Advanced control systems: CEIA USA's induction brazing machines feature advanced control systems that ensure precise temperature control and process monitoring.

- Safety certifications: CEIA USA's machines comply with relevant safety certifications, such as CE Marking and ISO 9001, ensuring that they meet stringent safety and quality standards.

- Reliable performance: CEIA USA's commitment to quality and reliability ensures that their induction brazing machines deliver consistent performance and minimize downtime.

Conclusion

Is induction brazing safe? By eliminating open flames and gas hazards, providing precise temperature control, and creating a cleaner work environment, induction brazing offers a safer, more efficient alternative to traditional brazing methods. With CEIA USA's induction brazing machines, industries can enjoy the benefits of induction heating brazing while maintaining the highest standards of safety and quality.

By adopting induction brazing technology, businesses can improve operator safety, reduce environmental impact, and achieve consistent, high-quality results. Whether you're in the automotive, aerospace, or manufacturing sector, induction brazing is a reliable and efficient solution for your joining needs.

Key Takeaways

- Induction brazing eliminates open flames and gas hazards, improving operator safety.

- Induction brazing machines offer precise temperature control, ensuring consistent results.

- CEIA USA's induction brazing machines feature advanced safety features and comply with international safety standards.

- Induction heating brazing is a cleaner, more energy-efficient process that reduces environmental impact.

By choosing induction brazing, you can enhance your production processes, improve safety, and achieve superior results. Explore the benefits of induction brazing today and discover how it can transform your joining operations.