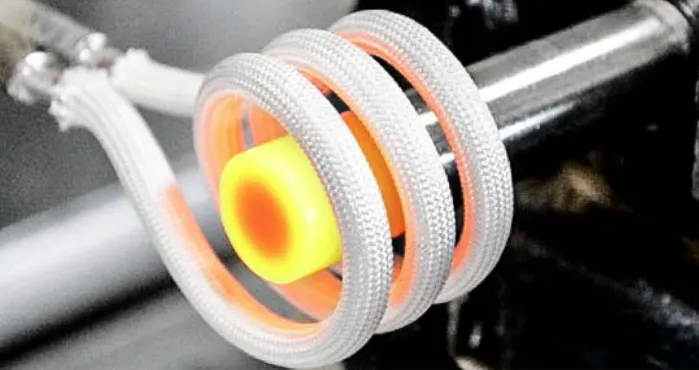

CEIA Induction Heating Solutions for the Fastener Industry

Induction heating is widely applied in the fastener industry to ensure precision, quality, and efficiency. By heating metals to controlled temperatures, the material’s malleability is maximized without allowing re-crystallization, grain growth, or metallurgical fractures. This improves quality, boosts productivity, and extends machine life.

Main Applications of Induction Heating in Fastener Production

1. Heating for Forging

- Used for stamping the head of screws.

- High temperature range: 950–1150°C.

- Heating localized at the rod extremity, with a length approximately three times the rod diameter.

2. Warm Forming

- Temperature range: 150–750°C.

- Inductors can be integrated directly inside the machine near the cutting station, or externally.

- Temperature depends on the metal: lower for steel, higher for titanium.

3. Pre-Heating Before Threading

- Temperature range: 300–600°C.

- The screws that have already formed require localized heating for the threading process.

- CEIA’s compact induction systems integrate easily into:

- Cylindrical 3–4 die machines (manual/semi-automatic).

- Flat die or planetary rotary threading machines (automatic).

4. Induction Hardening of Screw Threads

- Pre-heating screws to 100–300°C before applying thread-locking or sealing coatings.

- Ensures durability and performance of fasteners.

Why Choose CEIA Induction Systems?

- Compact design allows seamless integration into existing production lines.

- Continuous, reliable heating optimized for different metals.

- Improved efficiency and reduced downtime in fastener manufacturing.